What is an oil skimmer?

An oil skimmer is a device that can be used for extracting oils, debris, fats, and grease from water stored in pits or tanks. The extracted floating materials are accumulated by the equipment on a tube, rope, or belt.

How do belt oil skimmers work?

Baldwin belt oil skimmers extract oils, grease, and debris from water with an oleophilic (oil-attracting) tube. To remove floating oils and debris, the oleophilic belt is driven through a scraper in the main body of the skimmer system.

How do tube oil skimmers work?

Tube oil skimmers require a large operation area and use a plastic hose over the contaminated liquid, which then draws the water back through the drive unit to extract all impurities.

Which is better, a tube oil skimmer or a belt oil skimmer?

This largely comes down to preference and the nature of the job. If you favour having more coverage over the tank containing all accumulated water, you’re performing low clearance jobs, or require the oil skimmer to be side-mounted, you may prefer a tube oil skimmer. If on the other hand, saving space is the priority for you, then a belt skimmer would be ideal due to it taking less room while still easily accumulating oil from larger surfaces.

Why should you choose an Abanaki oil skimmer?

When it comes to supplying the right equipment, we stock Abanaki’s oil skimmers, due to their continued reliability and efficiency. We stock an exclusive range from Abanaki that will suit whatever type of job you need to complete.

An Abanaki oil skimmer provides better value than utilising an independent contractor for oil skimming. They’re considered to be one of the most inexpensive methods to separate oil from water. They preserve coolant life by removing tramp oils while ensuring it is efficiently disposed of, making them a step ahead of various other brands. They also lower all costs associated with fluid disposal, making them a strong option that’s packed with value.

With Abanaki’s history going back to 1949, they’re widely considered to be the world leader in oil skimming equipment, providing innovative solutions to controlling oil contamination. We believe our customers deserve the best which is why we rely on Abanaki’s oil skimmers.

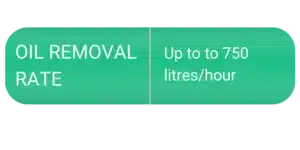

What is the oil removal capacity of an oil skimmer?

The oil removal capacity of an oil skimmer depends on the product itself. They can range from 4 litres per hour to an impressive 750 litres per hour. Your situation will determine the litres and type of oil skimmer you should choose.

Can any custom equipment be included with an oil skimmer?

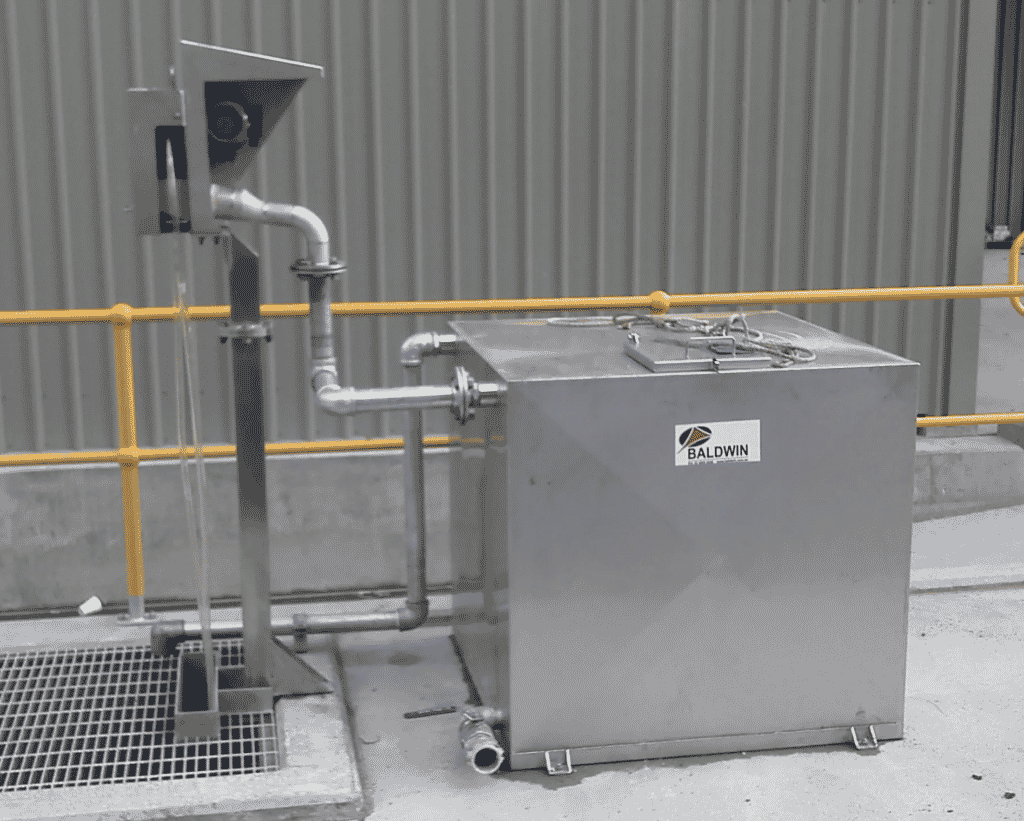

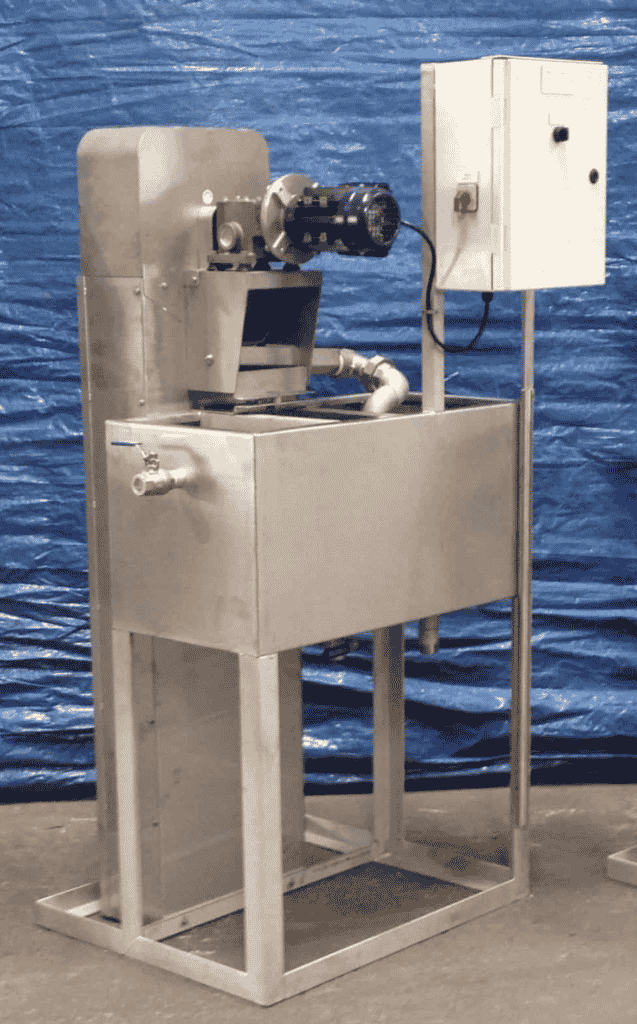

Custom equipment can be included with Baldwin’s oil skimmers, including custom-designed and fabricated stands and tanks, made specifically to match the job at hand.

Baldwin’s Product Range

Baldwin stocks a variety of oil skimmers from Abanaki to suit whatever job and application that’s required. We also offer custom-designed and fabricated stands and tanks to suit your workshop, site or specialised application. Our versatile range includes:

- Control panels

- Mounting stands (custom fabricated)

- Waste oil tanks (custom fabricated)

- Oil decanters or concentrators

- ExD motors for Zoned Areas

- Pneumatic motors for zoned areas

- Spare tubes and belts

Our range includes the Abanaki Mighty Mini Belt Skimmer for smaller jobs which also includes an inbuilt digital timer. It also includes The Abanaki Model 4/8 and Oil Viper for heavy-duty jobs.

Which Industries Are Abanaki Skimmers Used in?

When it comes to larger industrial applications, Abanaki belt/tube skimmers are an ideal choice. These skimmers are versatile and are commonly used as oil and water separator tools in a range of industries including:

- automotive

- mining

- industrial workshops

- food processing plants

- environmental monitoring wells

- wastewater

- outdoor ponds and dams

The heavy-duty Abanaki Model 4 or Model 8 Oil skimmers and the Abanaki Oil Viper Tube Skimmer, with tube lengths up to 100 feet, are all widely used in pits and tanks on mining and industrial sites.

Whatever type of job you’re trying to complete, at Baldwin we guarantee that our oil skimmers will benefit your company and most importantly, get the job done. For more information and guidance on which oil skimmer is right for you, call Baldwin Industrial Systems today at 02 4954 0440.